This is a somewhat classic case of solder joint fatigue failure, but with the added factor of gold embrittlement. The solder alloy is SN63, the package is a J-lead PMIC, and it is soldered to an alumina ceramic substrate.

The elemental spectrum of the bulk solder joint suggested it contained ~ 3 wt% of gold, which is considered a threshold for gold embrittlement.

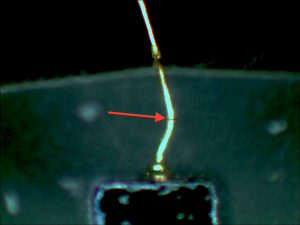

The thermal fatigue fracture showed classic characteristics such as grain boundary separation and propagation through the bulk solder joint.

The AuSn4 intermetallic compound is clearly visible in the solder joint microstructure at about 12% by area in the section. This harder phase in the Sn-Pb matrix likely accelerated the thermal fatigue failure.

The analysis results suggest that the thermal fatigue damage was likely due to the combination of (1) CTE mismatch between the J-lead package and the alumina substrate and (2) Au-Sn IMC in the solder joint microstructure at the threshold for gold embrittlement.

Check out SEM Lab, Inc. to learn more.