Electronic Component Failure Analysis of PCBs, PWBs, ICs, Chips, Transistors, Diodes, Capacitors, Resistors, LEDs, Power Modules, etc.

SEM Lab, Inc. is a failure analysis lab that specializes in electronic component failure analysis of assemblies, printed-circuit-boards (PCBs), printed-wiring-boards (PWBs), and electronic components such as integrated circuits (ICs), memory chips, transistors, diodes, capacitors, resistors, LEDs, power modules, and many others. We have analyzed electronic devices, components and assemblies for ESD, EOS, shorts, opens, corrosion, solderability, vibration, thermal fatigue, connector failures, etc.

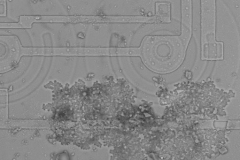

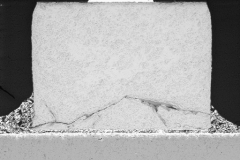

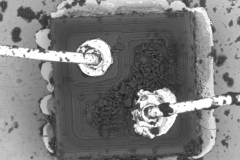

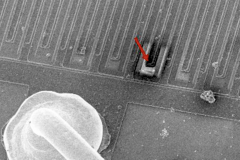

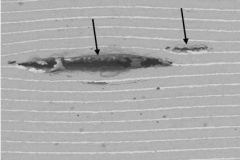

Failure Analysis of electronic components usually involves cross-sectioning and examination in the scanning electron microscope to provide accurate root cause failure analysis. The focus of the analysis is primarily on the quality of construction techniques used during the manufacture of these devices.

Some examples of device failure analysis can be found on our Device Examples page.

An excellent source of current and up-to-date examples of electronic component failure analysis can be found on our blog page. Comments and input are appreciated.

Component Failure Analysis

Device Failure Analysis

Failure analysis of electronic components can result in failure mechanisms that are different for every device or assembly. A more detailed look into the failures tailored to specific devices can be found here:

- Capacitors

- Resistors

- Inductors

- Diodes

- Transformers

- LEDs

- ICs

- PWBs

- BGAs

- PCBAs

- Identifying Counterfeit Components

- Medical Device Failure Analysis

Device Failure Analysis Documentation

Failure Analysis of Capacitors, Resistors, Inductors, Diodes, Transformers, LEDs, ICs, PWBs, BGAs, PCBAs

SEM Lab, Inc. has created some in-depth documentation of failure mechanisms we have seen in the last 22 years doing electronic component failure analysis. These include Intermetallics in Solder Joints, Failure Analysis of LEDs , Failure Analysis of BGAs, Gold Embrittlement of Solder Joints, Failure Analysis of PCBAs, Diffusion Barrier Plating in Electronics, Images of Failures in Microelectronic Packaging, Fourier Transform Infrared Analysis, Failure Analysis of Aluminum Electrolytic Capacitors, Solder Joint Analysis, HASL Finish on PWBs, PWB Failure Analysis, BGA Assembly Verification, and Solder Flux Residue – Part 1 and Part 2.

Within these documents SEM Lab, Inc. describes analyzing components for failure mechanisms such as generalized corrosion, bond pad corrosion, gold embrittlement, black pad syndrome (ENIG finished PWBs), plated-through-hole and via failures, electrical contact problems, wire bonds, BGAs, delamination, and electromigration. On-going current examples can also be found on our blog page.

Below are a few examples of electronic component failure analysis we have seen at SEM Lab, Inc. A more extensive gallery of device failures can be seen on our device failures page, as well as on-going examples on our blog.