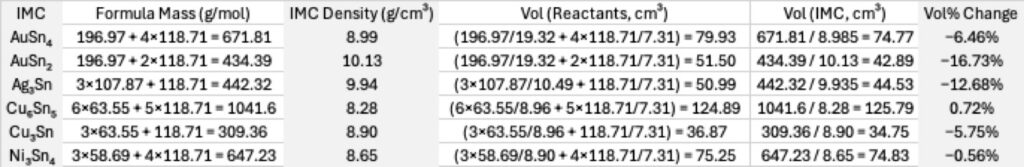

We can write equations and make calculations based on atomic weight & density of pure elements to determine what volume change (%) occurs when for example Au + 4Sn >>> AuSn4 and using intermetallic densities from published sources as shown in Fig. A.

Fig. A – Volume change during formation of solder intermetallic compounds.

Since volume changes during IMC formation, we can expect void formation and interfacial cracking at the IMC/matrix interface as most of these systems show contractions in volume. This may be a contributing factor to thermal fatigue damage found in solder joints on printed circuit board assemblies.

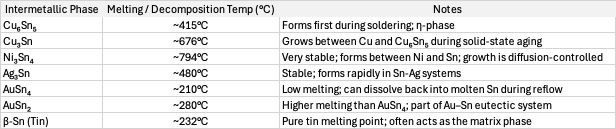

The melting temperature of these intermetallic compounds are shown in Fig. B. Most of these melting temperatures are greater than peak reflow temperature, so the IMCs exist as solid particles in molten solder until the system cools below the solidus temperature.

Fig. B – Melting temperature of intermetallic compounds.