Drilled Hole Roughness (Ra) as a Metric for PWB Reliability

Ed Hare, PhD – SEM Lab, Inc.

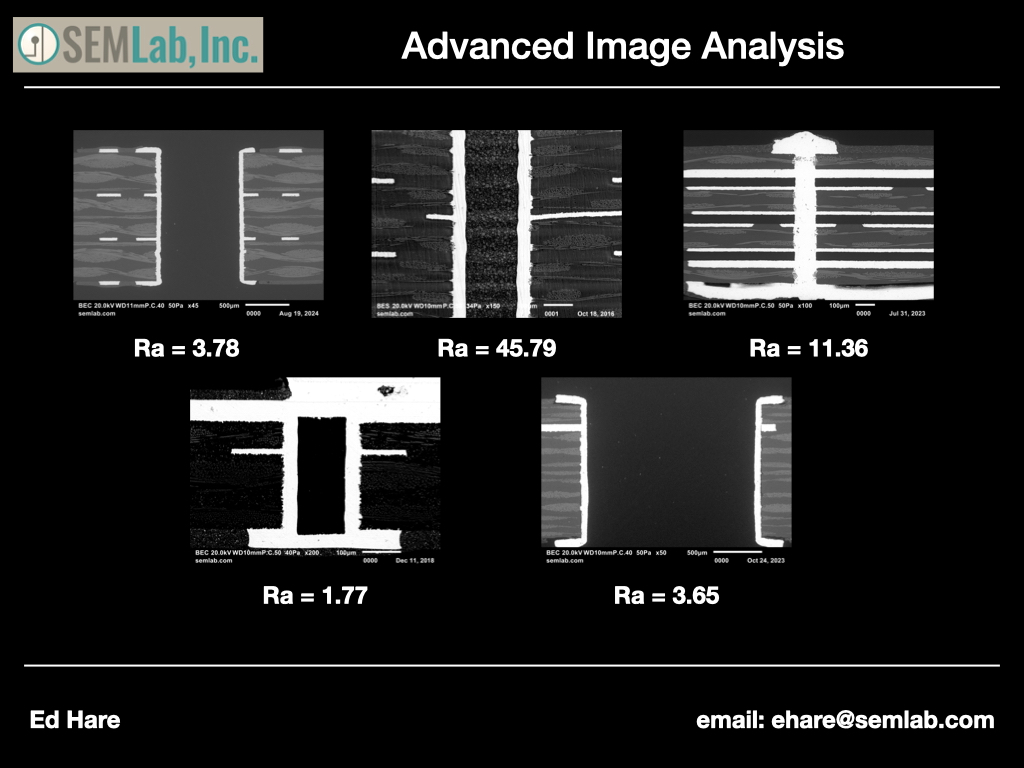

Drilled hole quality is often overlooked as a contributing factor to long-term reliability in printed wiring boards (PWBs). In particular, surface roughness of the drilled hole wall, commonly reported as Ra (arithmetic average roughness) or Rq (root-mean-square roughness), can have a significant impact on performance and failure risk.

⸻

Why Rough Drilled Holes Matter

Fabrication Indicator

Poorly drilled holes are often a fabrication quality issue—commonly related to drill bit wear, improper feed/speed, or inadequate desmear. Excessively rough drilled hole interiors are indicative of poor process control during board fabrication.

CAF Failures

Rough hole walls can create micro-crevices that promote conductive anodic filament (CAF) formation under applied bias and elevated humidity. These sites serve as initiation points for copper migration, especially in high-density multilayer designs.

Electrical Noise

Non-uniform copper topography inside the via barrel may also contribute to electrical performance variation in high-speed or RF applications. These effects are often masked during initial testing but become problematic under long-term use.

Stress Risers

Jagged or mechanically damaged areas along the drilled wall act as stress risers, which can limit fatigue life under thermal or mechanical cycling. This often results in copper barrel cracking or interconnect failure over time.

⸻

Measurement and Analysis

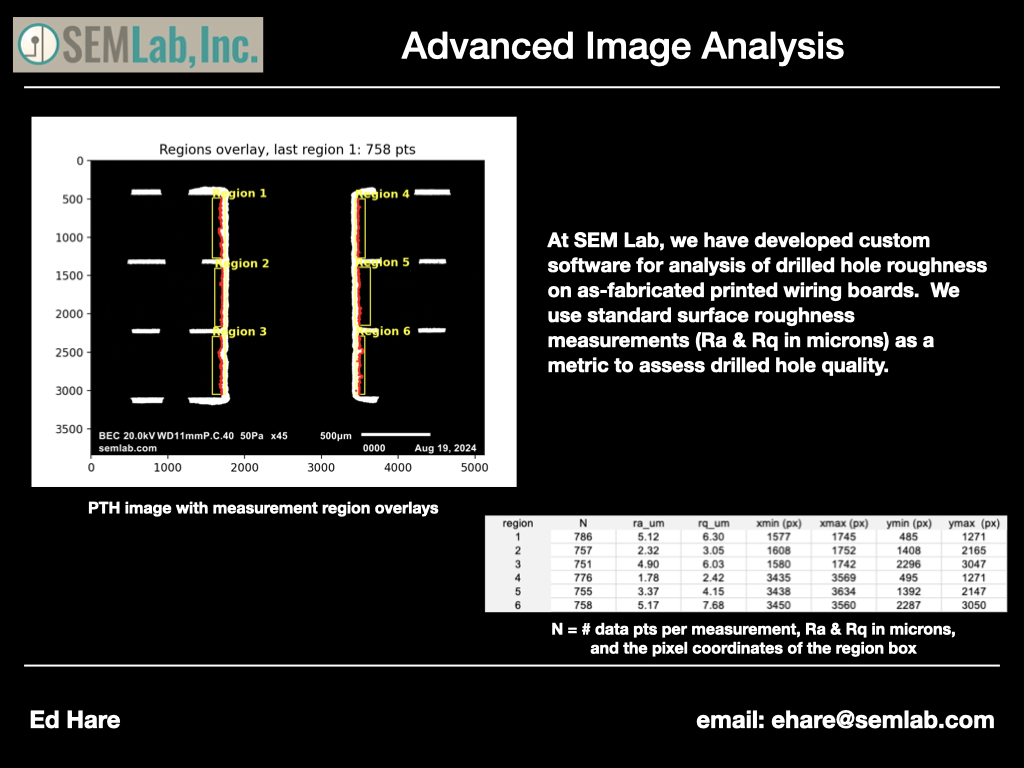

At SEM Lab, we use high-resolution SEM imaging and software-based analysis to calculate Ra and Rq from drilled hole interiors. Measurements are obtained from multiple regions of interest within the via structure, and plotted against PWB lot, drill column, or via position.

This approach allows for identification of outliers caused by tool wear or board stack variation. Regions with elevated Ra values may correlate with plated copper pull-away or localized delamination when subjected to thermal cycling.

⸻

🔧 Recommendations

• Evaluate Ra and Rq from representative drilled holes on each new PWB lot.

• Use SEM or profilometry tools—optical inspection is insufficient for identifying roughness-based failure risk.

• Set internal benchmarks (e.g., Ra < 2.0 µm) for critical layers and high-reliability applications.

• Include drilled hole roughness as a QA parameter when auditing new board suppliers.

⸻

Support Available

SEM Lab Inc. now offers remote consulting services to support engineers involved in resolving product quality issues. If you’re encountering via-related failures or want to strengthen your board qualification process, I can assist by reviewing failure data and providing recommendations based on decades of laboratory experience.

📧 ehare@semlab.com

🌐 www.semlab.com