Conductive anodic filament (CAF) failure has become a critical reliability concern in modern printed wiring boards (PWBs). As designs push toward finer pitch, higher layer counts, and higher operating voltages, the risk of CAF increases. CAF refers to the growth of a conductive copper filament through the glass/epoxy dielectric under bias and humidity, bridging adjacent conductors. These failures typically occur below the surface of the laminate, making them difficult to detect until electrical breakdown occurs.

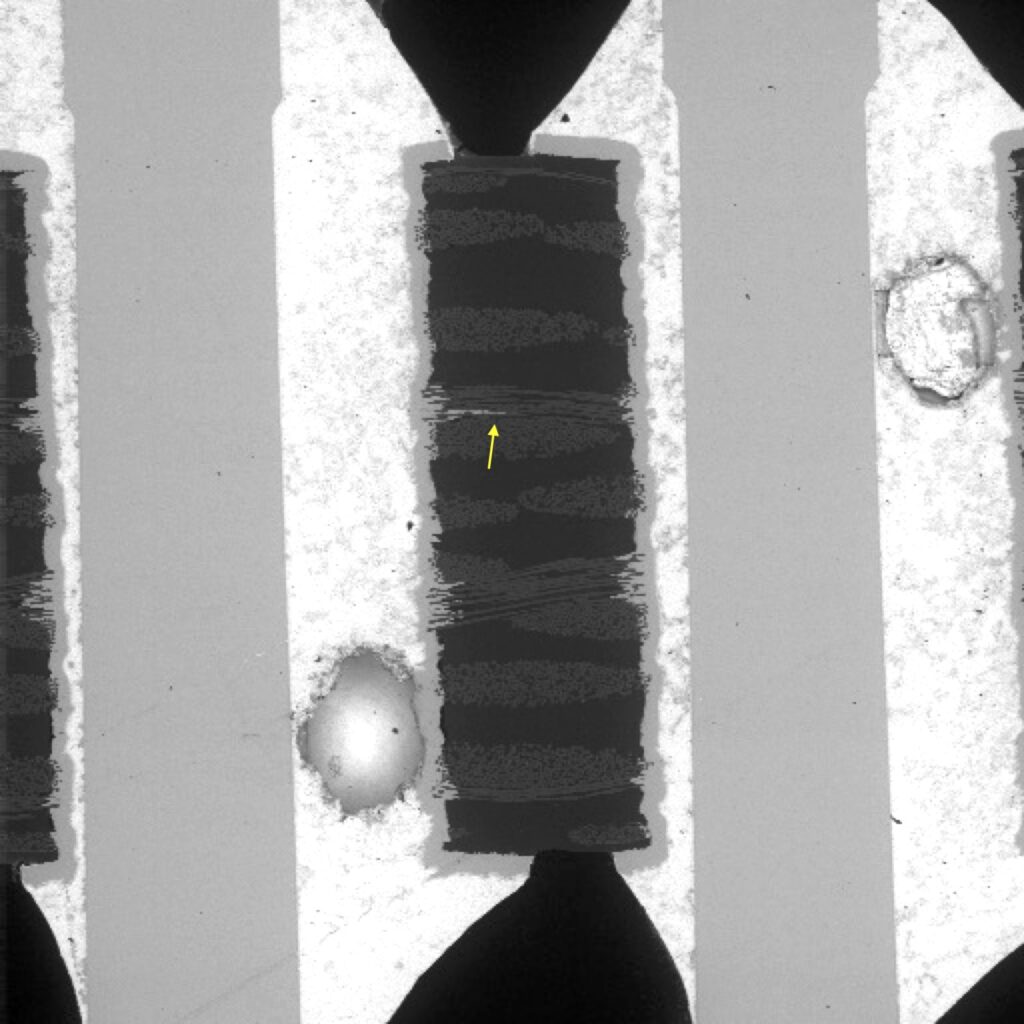

Fig.1 – Plated copper is deep in the dielectric space between holes in the laminate.

CAF formation is often associated with copper plating extending beyond the plated through hole wall into adjacent resin-rich regions. Once copper is introduced into these dielectric pathways, bias and moisture accelerate ion migration. The resulting copper grows along glass/resin interfaces, creating hidden conductive bridges deep inside the laminate stack.

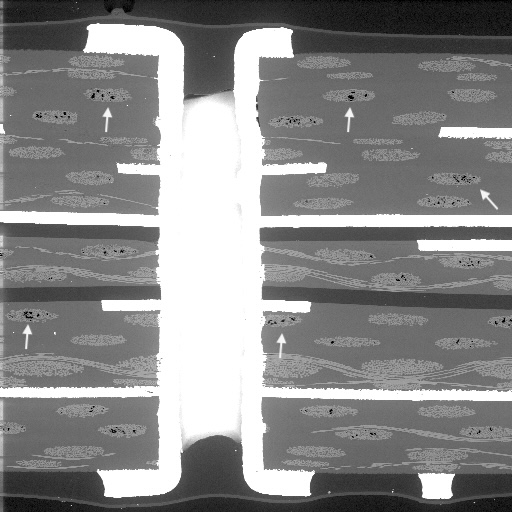

Fig. 2 – Failures were caused by CAF between +12V and GND at a connector.

CAF is particularly insidious when it forms between high and low potential conductors, such as +12 V and ground nets. Even small leakage currents can result in intermittent failures, system resets, or complete short circuits.

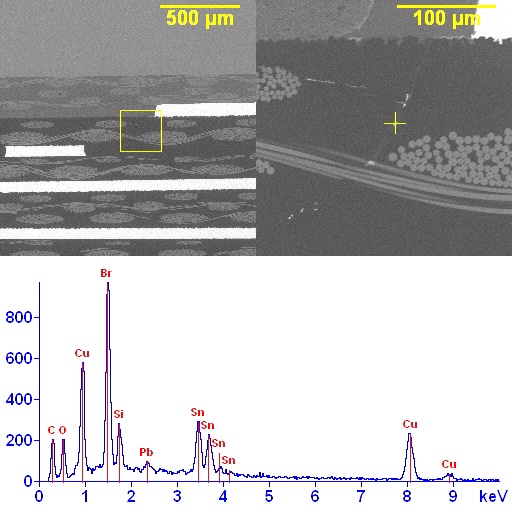

Fig. 3 – Resin starvation in glass bundles can cause CAF failure.

Areas where resin coverage is poor around glass bundles provide prime initiation sites. Resin starvation leaves microvoids and channels at the fiber-resin interface. These gaps act as capillaries for moisture and ionic species, establishing a pathway for CAF growth. Process controls during lamination—such as ensuring proper resin flow and glass fabric wetting are therefore crucial to prevention.

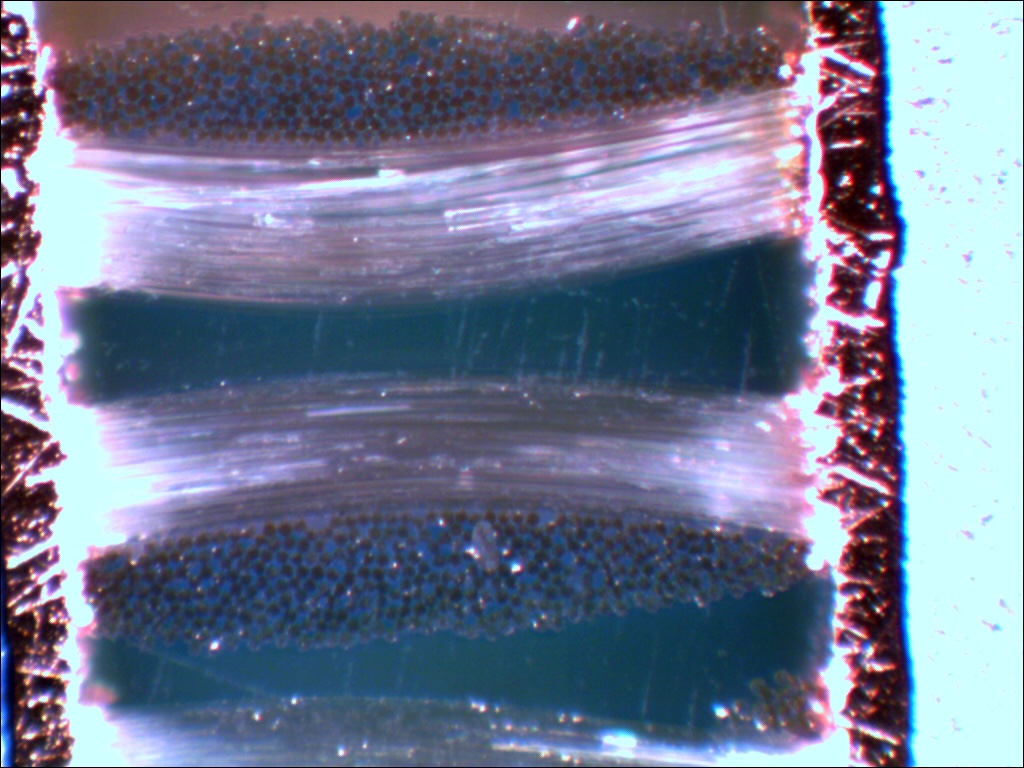

Fig. 4 – Crazing and measling of laminate can support CAF failure.

Crazing and measling are microcrack and void patterns associated with glass bundle movement or thermal-mechanical stresses. These features effectively increase the available surface area and pathways for CAF propagation. A laminate that visually shows measling may already harbor hidden weaknesses that accelerate conductive filament growth under bias and humidity stress testing.

Fig. 5 – Dark field optical images can be useful for examining fiber delamination in PWB sections.

Optical microscopy, particularly in dark field mode, highlights fiber pullout, voiding, and microcracking within cross-sections. These imaging techniques provide valuable insight into resin-glass integrity and delamination. Proper sectioning and imaging remain vital diagnostic steps in CAF investigations.

Conclusion

CAF originates inside the laminate microstructure, where resin-glass interfaces and plating intrusions provide pathways for copper migration. Once established, these conductive filaments undermine reliability and are difficult to detect by conventional inspection. Effective CAF prevention requires careful control of laminate fabrication, resin distribution, and design spacing rules, coupled with targeted failure analysis methods when issues arise.