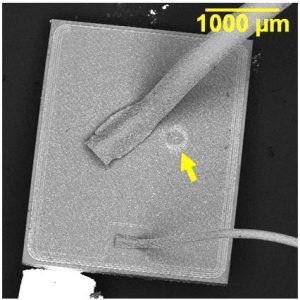

SEM/EDS is useful for detecting the use of red phosphorus in IC molding compounds.

At one time (~1990s), red phosphorus was introduced as an environmentally-friendly flame retardant in molding compounds for semiconductor devices.

This turned out to be a mistake.

A rash of electrical leakage related failures ensued.

There are now reports of red phosphorus use in wire insulation for cabling and power cords, suggesting that the industry may not have learned its lesson.

Check out SEM Lab, Inc. to learn more.