Resistor Corrosion Failures Associated with Flux Residues and Protective Layer Breakdown

Ed Hare – SEM Lab, Inc.

Analysis of multiple case histories shows that resistors are vulnerable to corrosion when flux residues, halide contaminants, and weak protective layers interact. These failures are not isolated anomalies; they represent a recurring set of conditions tied to assembly practices, cleaning processes, and material compatibility.

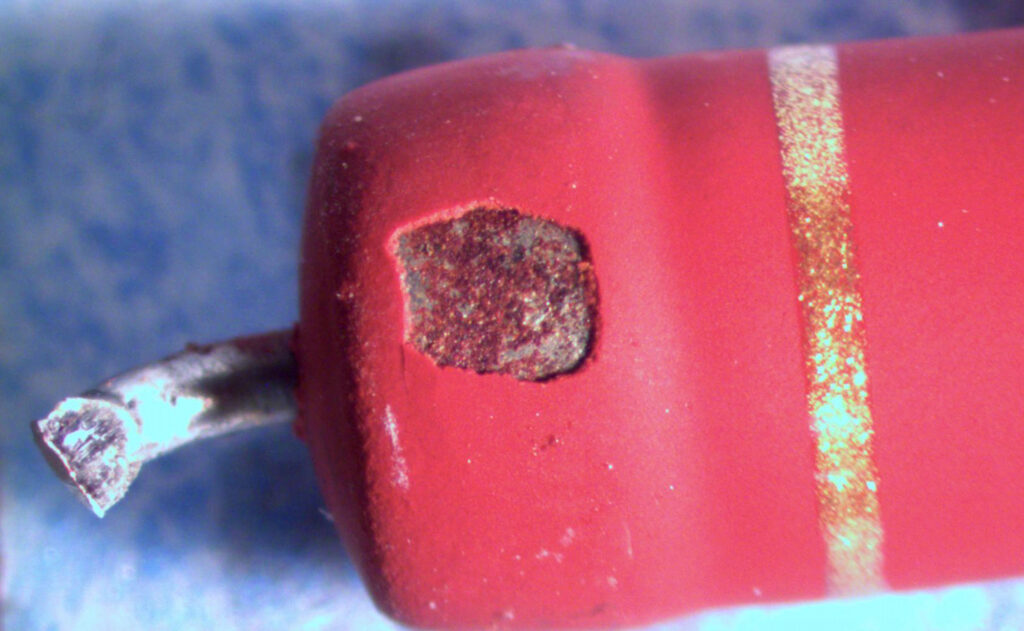

In one study, resistors exhibited rusted end caps beneath failed paint layers. Once the protective paint fractured, chloride-bearing residues penetrated and initiated corrosion at the steel end caps. This ingress path was a consistent feature across samples.

Figure 1 – Optical view of end-cap paint failure.

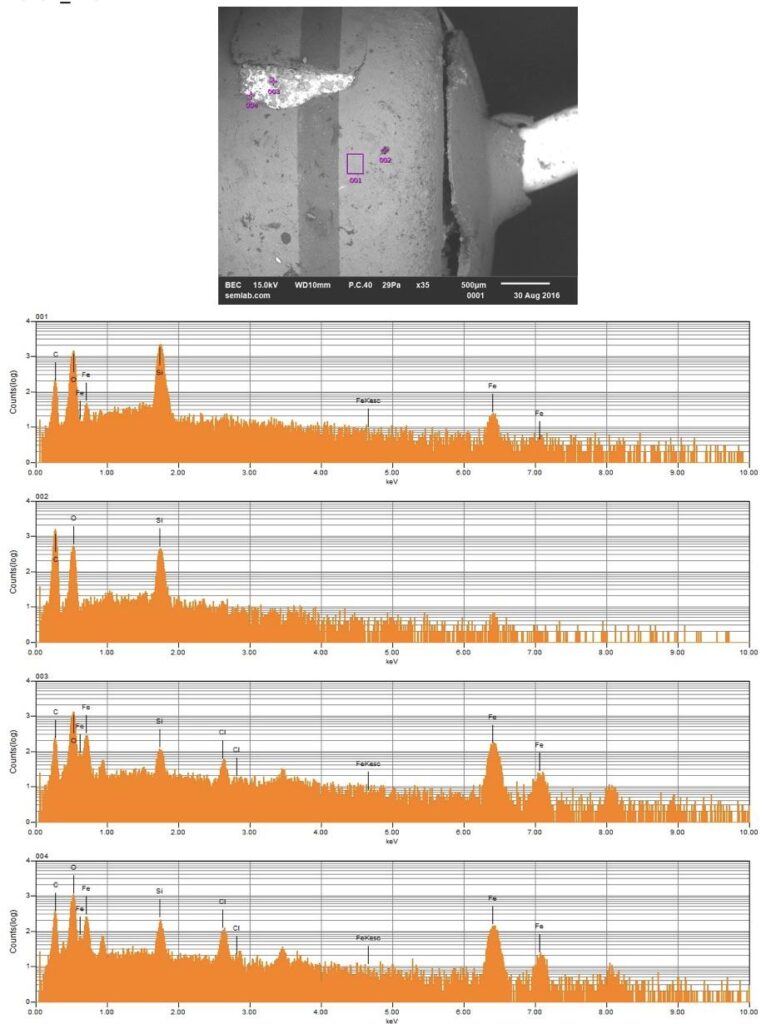

Backscattered SEM and EDS analysis confirmed that rust developed beneath the paint, with chlorine contamination detected in the affected regions. The presence of halides strongly implicates solder flux and cleaning residues as the root source.

Figure 2 – SEM/EDS of corrosion under paint layer.

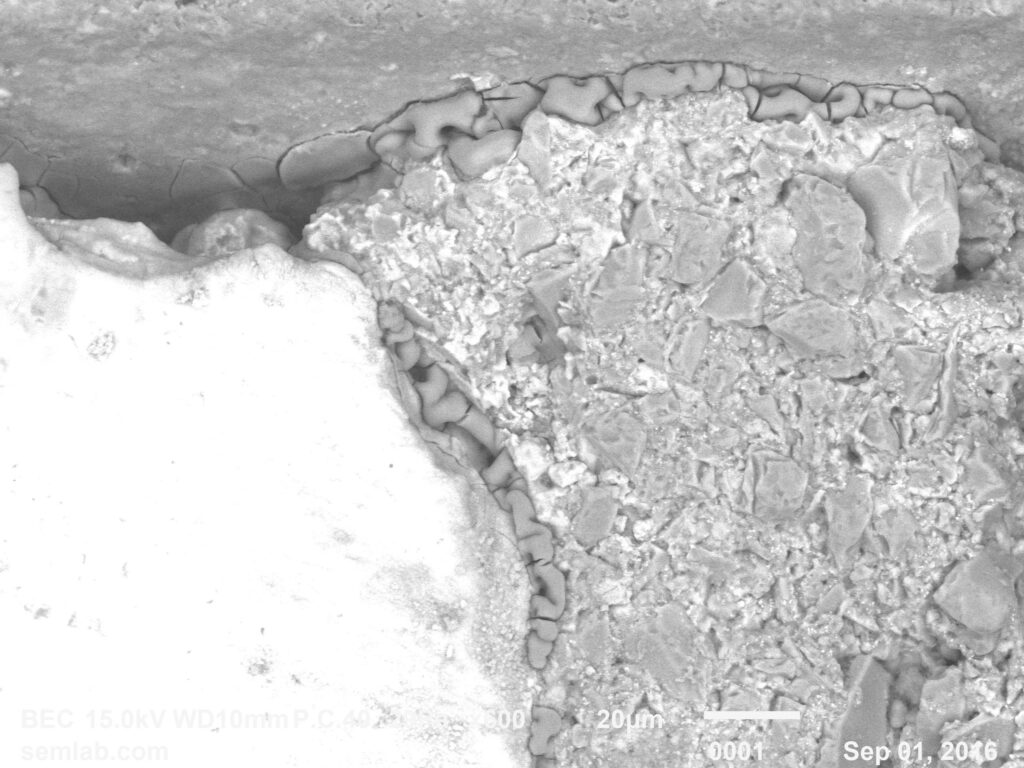

The corrosion was not limited to the cap itself. In several cases, the attack extended to the resistive film where it joined the termination, producing variable resistance and eventual opens.

Figure 3 – SEM image of resistive film attack.

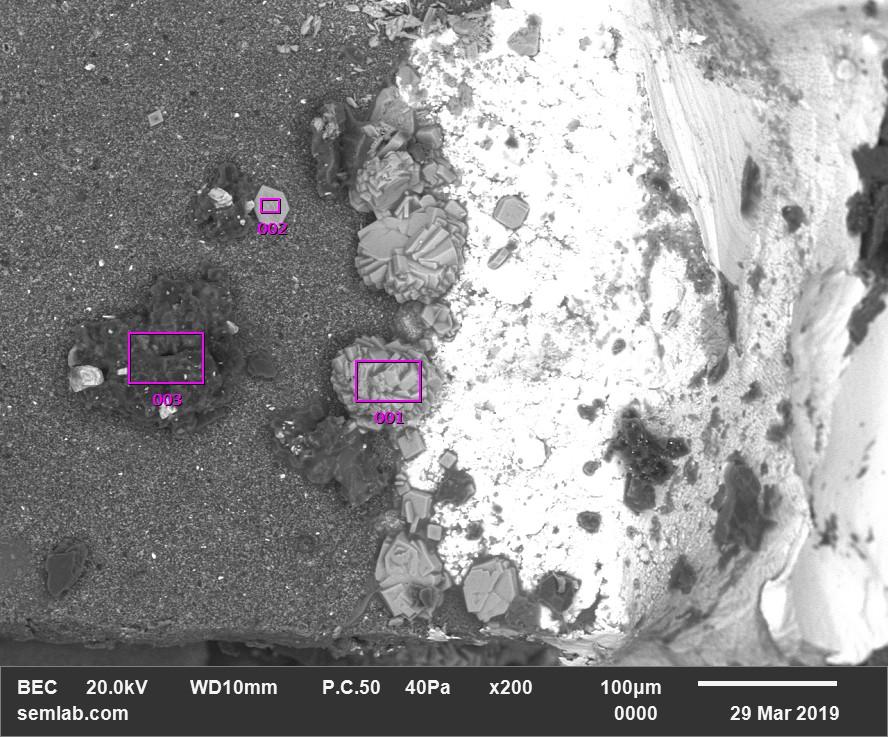

Other resistor types showed crystalline corrosion products directly on their terminations. SnO₂ crystals were identified at the surface, again associated with flux residues containing chlorine, sulfur, and phosphorus. These crystalline deposits physically bridge surfaces and act as local ionic conductors.

Figure 4 – Corrosion crystals on resistor termination.

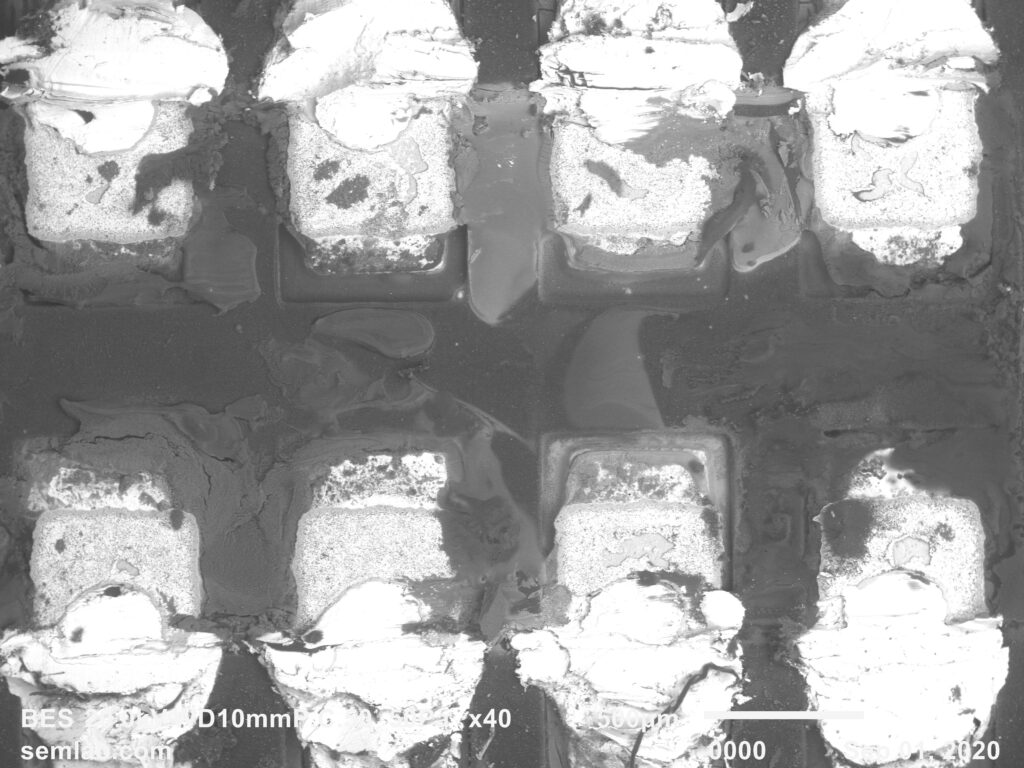

For network packages, the failure mechanism was often contamination trapped beneath the component. SEM sections revealed a mixture of corrosion products and solder flux beneath the resistor arrays, exactly in the spaces that are inaccessible to normal cleaning. These residues were electrically active, producing leakage and shorts between adjacent signals.

Figure 5 – Corrosion and flux residue trapped under a resistor network.

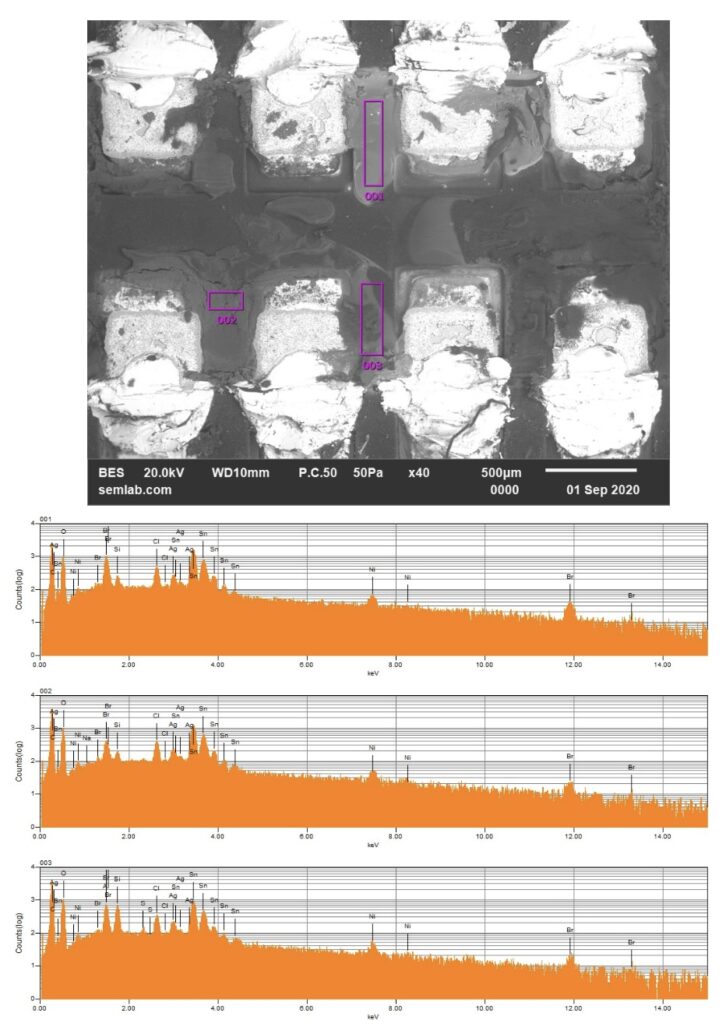

Elemental analysis of the trapped material confirmed carbon, oxygen, tin, and high levels of chlorine and bromine—classic signatures of flux activators.

Figure 6 – EDS spectra of halide-rich residues.

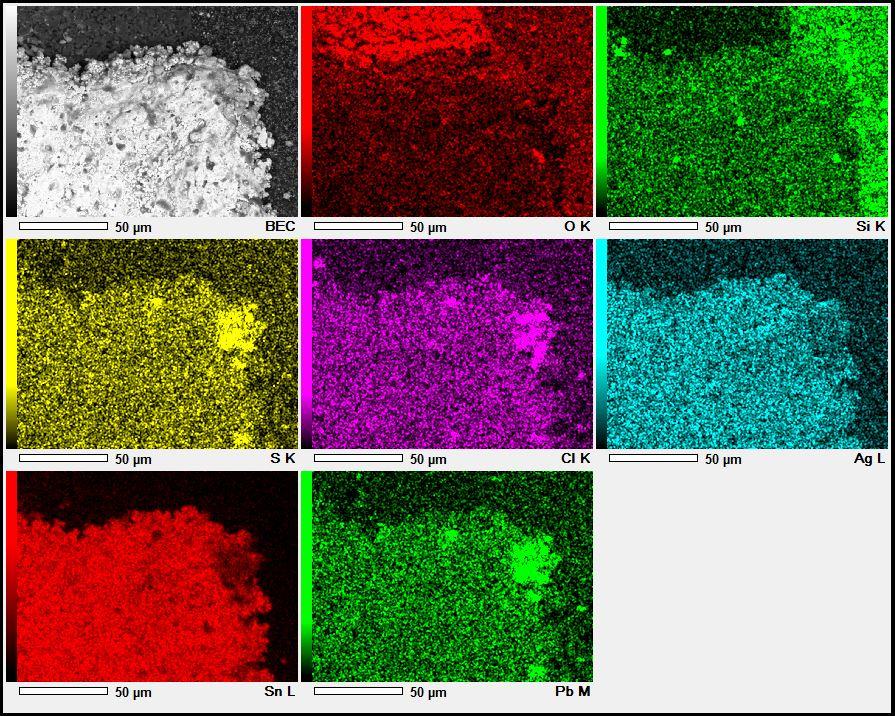

Thick-film resistor terminations proved especially susceptible to sulfur attack. Elemental mapping showed sulfur and chlorine concentrated at the silver film layer, producing degradation of the conductive path. This highlights the material sensitivity of silver-based resistor films to environmental residues.

Figure 7 – Elemental map of thick-film resistor corrosion.

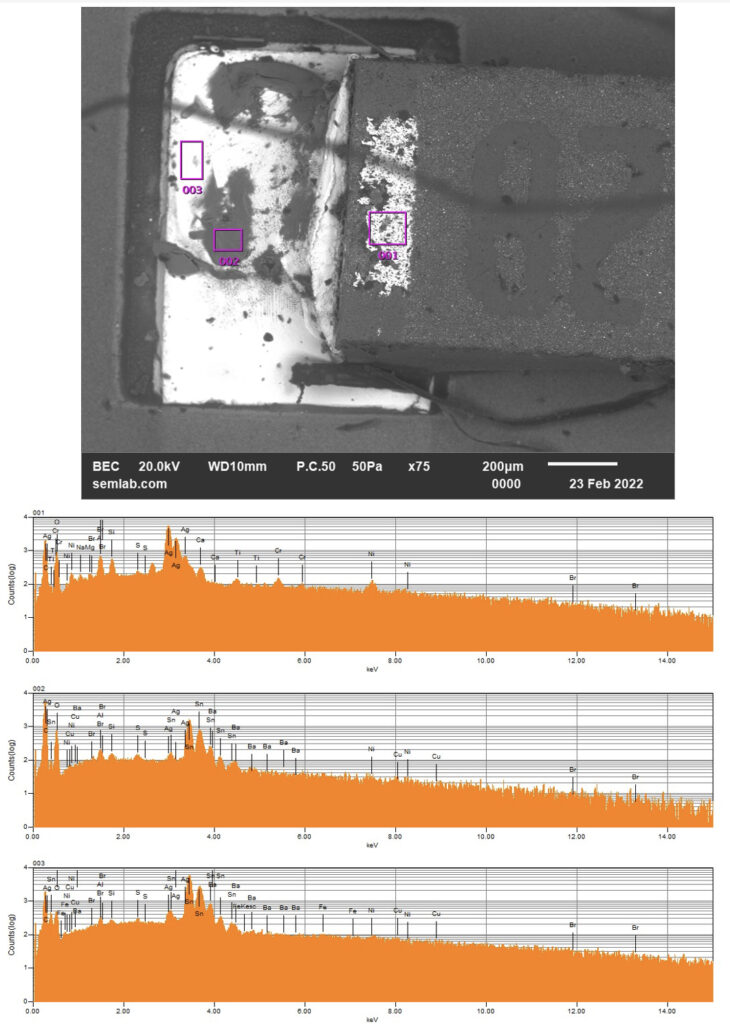

Finally, some failures were linked to process-induced damage. Secondary solder touch-up operations created fractured nickel plating and left flux residues on resistor terminations. In these cases, corrosion was not the only factor; mechanical disruption of the plating accelerated failure at the solder joint interface.

Figure 8 – Flux and mechanical termination damage.

⸻

Discussion

Across these case studies, a consistent theme emerges: halide contamination from flux and cleaning residues is the dominant driver of corrosion. Once protective barriers such as paint layers, solder masks, or conformal coats are compromised, chloride and sulfur species attack both the termination metallization and the resistor element itself.

The resulting damage pathways—rusted end caps, SnO₂ crystal formation, halide-rich residues under networks, sulfur attack on silver thick film, and fractured nickel plating—lead to the full range of electrical consequences: variable resistance, open circuits, leakage currents, and shorting between nodes.

Conclusion

The reliability of resistors depends not only on their intrinsic design but also on assembly and cleaning discipline. Avoidance of aggressive flux chemistries, thorough removal of ionic residues, and protection of vulnerable interfaces are critical. These cases demonstrate that when those controls are absent, resistor corrosion becomes an inevitable and costly failure mechanism.