A client provided some sample PCBs (1 bare, 1 assembled) that were exhibiting discoloration on the ENIG plated surface. The client asked us to characterize this defect and determine root cause.

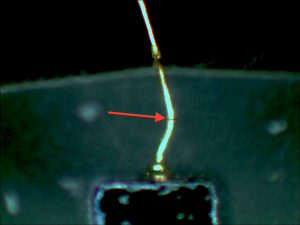

The nickel (EN) deposit appears normal except at the interface with the gold (IG layer). The defects (shown by the yellow arrows) are referred to as “IG spiking”, where the gold plating solution etches the Ni-P grain boundaries. This creates small voids or pits under the IG plating that trap process chemistry and cause corrosion resulting in the stain on the surface. Root cause = IG spiking. A secondary cause is water droplets left on the board surface after cleaning.

Check out SEM Lab, Inc. to learn more.